Production methods

Our environment-controlled ripening and storage rooms, our exclusive patented process, our efficient environmentally friendly technologies, and our rigorous quality control… all guarantee the exceptional freshness and quality of our products for our customers.

Production areas

Groupe Tomapure operates two production areas where, every day, a team of more than 40 proactive, hard-working individuals contributes to the quality of our garden produce.

- A decontamination and packing area for fruits and vegetables. Products are sorted, washed, decontaminated, “debacterialized”, dried and, finally, packaged according to industry standards.

- A custom packaging area to meet the demands of foodservice customers who require specific package formats based on amounts, or that meet the different needs of consumers.

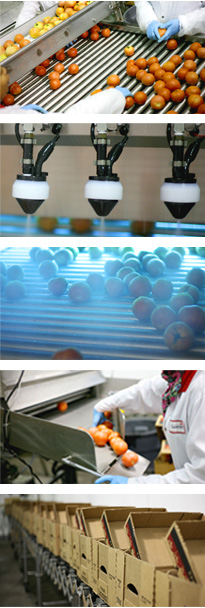

Production stages

The first step in our production line consists of three phases leading to the sorting and disinfection of products.

The first step in our production line consists of three phases leading to the sorting and disinfection of products.

Phase 1

It all starts by feeding the system, that is to say, with the arrival of goods at our facilities. The products are then sorted systematically according to colour, ripeness and overall level of quality. This ensures that they meet our very high standards.

Phase 2

The selected products are transported to the washing station where an electrostatic technology comprising eight nozzles sprays a controlled mixture of water and sanitizer (chinook) such as broad spectrum peroxyacetic acid—a derivative of vinegar and an ecological product that complies with environmental standards and Health Canada (Canadian Food Inspection Agency) standards — on fruits and vegetables. The products are then dried with air knives.

Phase 3

The crucial disinfection phase uses advanced UV radiation technology for at least six seconds, the minimum exposure time required to kill bacteria in microorganisms. Thanks to this technology, we can significantly reduce deposits and the presence of microorganisms such as salmonella, listeria monocytogenes, E.coli, staphylococcus aureus, bacillus, yeasts, molds and others. Studies have shown that the shelf life of vegetables treated with this patented technology can be extended by seven days, depending on the environment, when compared to the regular shelf life of unwashed vegetables. The result? Safe, quality products that meet MAPAQ standards and the needs of consumers.

Based on our continuous research and development efforts, we developed a vaporization station featuring electrostatic spray nozzle technology. This highly innovative technology allows us to wash the surface of our products more efficiently, which significantly increases our leadership position in the ready-to-eat (RTE) category. In addition, the system helps us reduce consumption of our wash water by approximately 80%, thus meeting the requirements of our sustainable development program.

Our products are safer than untreated organic products and the Canadian Food Inspection Agency (CFIA) has approved the use of our sanitizer for spraying and soaking fruits and vegetables. As a result, we are able to guarantee ready-to-eat freshness to our customers.

Safety first! To avoid any risk of contamination, all boxes used during the process undergo the same vapor spraying treatment as our products.